Fertilizer Granulator Machine Comparison: Rotary Drum vs. Disc Granulator

In the world of fertilizer manufacturing, granulation is one of the most crucial stages. It’s where raw powders are transformed into uniform granules—easy to handle, store, and apply. If you’re in the fertilizer business or considering setting up an NPK compound fertilizer production line, choosing the right granulator machine can directly impact your efficiency, quality, and profitability.

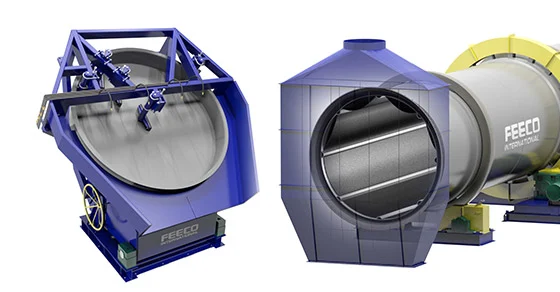

Two of the most widely used granulator types in the NPK fertilizer production line are the rotary drum granulator and the disc (pan) granulator. Each has its own strengths and considerations. In this guide, we’ll compare them in detail to help you make an informed decision—and explore how trusted brands like Cementl offer reliable, durable machines for both types of granulation processes.

Why Granulation Matters in NPK Fertilizer Production

NPK fertilizers—rich in Nitrogen (N), Phosphorus (P), and Potassium (K)—are essential for healthy plant growth. Granulation ensures that these nutrients are uniformly distributed in each particle, providing even release into the soil.

Granules also reduce dust, improve flowability during packaging and application, and enhance the fertilizer’s appearance and shelf life.

Rotary Drum Granulator: High-Volume Performer

How It Works:

The rotary drum granulator uses a rotating cylindrical drum to agglomerate powder materials into granules. Raw materials are fed into the drum, where moisture and rolling motion bind them into spherical shapes. A drying process follows to harden the granules.

Key Advantages:

- High output capacity: Ideal for large-scale production lines (10–30 tons/hour).

- Consistent granule quality: Especially suitable for NPK compound fertilizer production lines.

- Long operational life: Cementl’s rotary drum granulators are built from high-grade steel for long-lasting performance.

Considerations:

- Larger footprint: Requires more space and structural support.

- Higher initial cost: But pays off with long-term efficiency and volume.

- More complex setup: Installation and alignment must be precise.

Disc Granulator (Pan Granulator): Compact and Cost-Effective

How It Works:

The disc granulator has a rotating pan with adjustable tilt. As the pan turns, powders are sprayed with water or binders. The rolling motion forms granules, which grow layer by layer and are collected once they reach the desired size.

Key Advantages:

- Simple structure: Easy to operate and maintain.

- Cost-efficient: Lower upfront investment, ideal for startups and small to medium production capacities.

- Space-saving: Fits easily into smaller NPK fertilizer production line setups.

Considerations:

- Lower production volume: Usually up to 6 tons/hour, best for moderate output.

- More manual control: Requires skilled operators for optimal granule size control.

- Slightly less uniformity: Compared to drum granulators in large-scale plants.

NPK Fertilizer Production Line: Which Granulator Is Best?

Choosing between rotary drum and disc granulators depends on several factors:

| Factor | Rotary Drum Granulator | Disc Granulator |

| Production Volume | High (10–30 TPH) | Medium (1–6 TPH) |

| Space Requirement | Larger | Compact |

| Cost (Initial) | Higher | Lower |

| Automation | Easily integrated | More manual |

| Granule Uniformity | High | Moderate |

| Maintenance | Moderate | Low |

Cementl: Reliable Granulator Solutions for Every Scale

Whether you’re building a new NPK compound fertilizer production line or upgrading an existing one, Cementl provides high-performance machinery tailored to your needs. Their granulators—both rotary drum and disc—are engineered for durability, energy efficiency, and minimal downtime.

Why choose Cementl?

- Custom machine sizing based on your plant capacity

- Durable construction with corrosion-resistant materials

- Post-sale support including installation guidance and spare parts

- Integration with drying, cooling, and packaging systems

Many successful fertilizer plants around the world trust Cementl for both their NPK fertilizer production line and general processing needs.

Final Thoughts: Choose Smart, Build Strong

Selecting the right granulator machine is one of the most important decisions when setting up a fertilizer production facility. If you’re planning a large-scale operation, the rotary drum granulator is your best bet for efficiency and scalability. For smaller plants or budget-conscious startups, the disc granulator offers excellent value with good output quality.

Whichever path you choose, pairing your production line with trusted equipment from Cementl ensures your business starts on a solid foundation. From NPK fertilizer production line machines to comprehensive design and support, Cementl delivers solutions you can grow with—literally and financially.