Which Facial Tissue Machinery Fits Your Production Line

Choosing a facial tissue paper machine with strong control systems, proven certifications, and industrial-grade durability is critical to achieving operational efficiency, product consistency, and workplace safety.

What Key Criteria Should You Use to Select a Facial Tissue Machinery?

Here are the major considerations you must evaluate when selecting a Facial Tissue Machinery line.

1. Define Production Goals

Determine target output, lanes, SKUs, and change-over frequency. Match machine capacity to your production needs to avoid under- or over-investing.

2. Consider Raw Materials & Product Specs

Choose the right pulp or fiber (virgin, recycled, bamboo) and ensure the machine handles different weights, sizes, and folding formats.

3. Evaluate Automation & Integration

Fully automated lines reduce labor and boost efficiency; semi-automatic may suit smaller factories. Mingyang Machinery offers lines up to 160–200 packs/min.

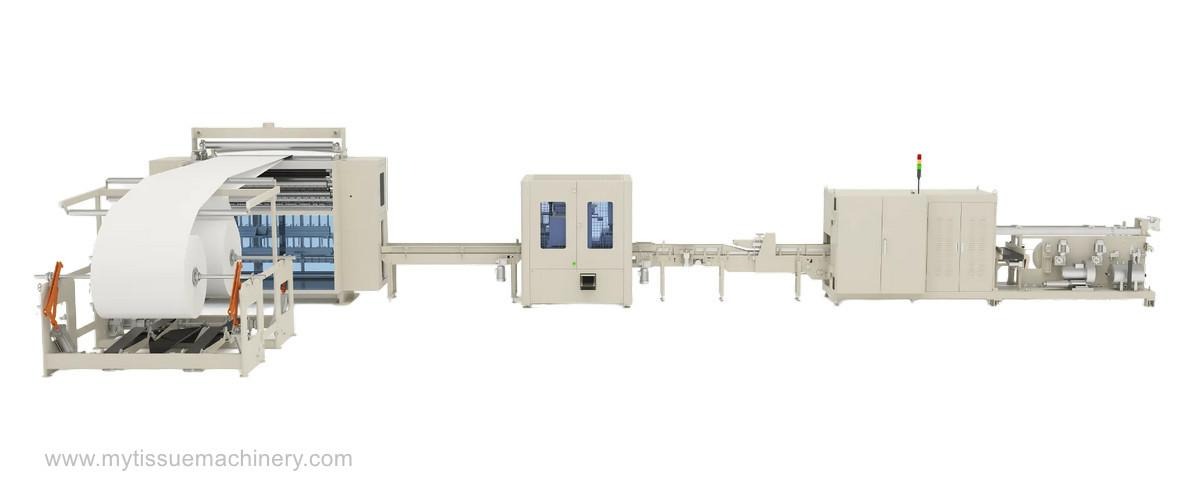

4. Check Components & Build Quality

Focus on jumbo roll unwinding, embossing, slitting, folding, and packing systems. Stability, durability, and easy maintenance ensure long-term ROI.

5. Assess Support & Manufacturer Credibility

Select a manufacturer with proven experience. Ensure they provide installation, training, spare parts, remote diagnostics, and maintenance planning.

How to Match Different Scales of Production with the Right Machine Type

Let’s match typical factory scales to suitable machinery options.

Small-Scale / Startup Facility

Characteristics: lower output (e.g., <0.5 tonne per shift), limited space and capital, fewer SKUs, simpler packaging.

Fit: Semi-automatic or lower-speed automatic Facial Tissue Machine. For example, some lines from Mingyang support output ~0.6T/8h in a compact footprint (~50-70 m²).

Medium-Scale Facility

Characteristics: moderate output (1-5 tonne per shift), moderate packaging complexity, multi-SKU, some growth plans.

Fit: Fully automatic line with flexible specification. The example from Mingyang supports 160-200 packs/min, with space of ~24.6 × 11.4 m².

Large-Scale / Export-Driven Facility

Characteristics: high output demands, multi-lane lines, multiple product formats, minimal labour per tonne, premium branding.

Fit: High-speed multi-lane Facial Tissue Machinery (600+ sheets/min/lane, 5-10 lanes) with packaging integration, robotics, predictive maintenance systems. As cited, “modern machines achieve output speeds exceeding 2,000 pieces/minute while reducing labour requirements by 65%.”

Which Features Should You Ask For When Specifying the Machine?

| Feature | What to Look For and Why It Matters |

|---|---|

| Embossing and Texture Options | If your brand targets “premium soft” tissues, select machines with embossing units (steel-to-steel or steel-to-rubber) and adjustable roller pressure. These allow you to control pattern depth, enhancing softness and bulk for a more luxurious feel. |

| Flexibility in Finished Size / Pack Format | A machine that can produce multiple sizes and folding types provides greater market flexibility. Look for lines that support soft-pack facial tissue, box-pack tissue, and hanging tissue formats in one system. Mingyang offers multifunctional production lines with these capabilities. |

| Modularity & Upgrade-ability | Choose equipment with modular components — such as folding, slitting, or packing units — that can be upgraded or replaced as your production needs grow. This design approach protects your long-term investment and simplifies future scaling. |

| Control System & Monitoring | Advanced systems with PLC control, touch-screen HMI, automatic fault detection, remote monitoring, and predictive maintenance alerts can help minimize downtime and optimize production performance. |

| Energy Efficiency & Environmental Compliance | As pulp and energy costs rise (notably, pulp prices increased by around 22% in 2023), prioritize machines that incorporate waste heat recovery, reduced power consumption, and compliance with modern environmental standards. |

When Should You Upgrade or Choose a New Machine?

You may ask: When is the optimal time to invest in or upgrade a facial tissue production line?

- When your utilisation consistently exceeds ~80% of current machine capacity and you anticipate market growth (sales channels expanding, new SKUs, export demand).

- When downtime and scrap rates start rising significantly due to wear or outdated mechanical control.

- When your product specifications (size, pack format, embossing) change and current machine lacks flexibility.

- When new regulations or raw-material shifts (e.g., move to recycled pulp) require upgraded technology for process stability.

One guideline suggests that machines older than 8-10 years often lag in automation, efficiency, and maintenance cost — prompting upgrade discussions.

Summary

- Clarify your output, product formats, raw material types and future growth.

- Match that with the automation level, build quality, and flexibility of a machine line.

- Review supplier credibility, experience, after-sales support and global service footprint.

- Evaluate additional features such as embossing, packaging flexibility, monitoring systems and energy efficiency.

- Be realistic: choose a machine scale that aligns with current production and allows for growth, rather than simply buying the biggest machine you can afford.

If you apply that methodology, you’ll select the Facial Tissue Machine that truly fits your production line — avoiding underperformance or over-investment. Mingyang Machinery offers strong options in this regard, backed by patents, global service and custom solutions.