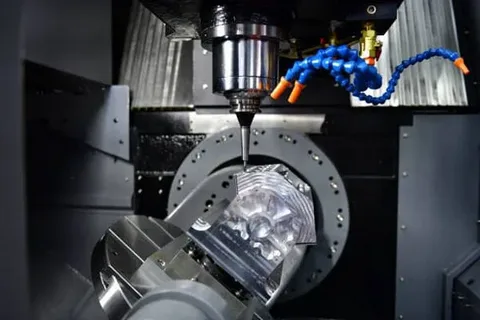

5 Axis CNC Machine Helps Make Very Accurate Products

A CNC machine is a special computer-controlled tool that can move in five different ways to shape materials like metal or plastic. This machine can make very precise cuts and detailed work on a piece of material from almost any angle. Unlike simple machines that might only move in two or three directions, a 5 axis machine can tilt and rotate around multiple axes while it works.

How CNC Machines Perform Tasks?

The key to understanding a CNC machine is its ability to move along five different axes at the same time. When you need precise manufacturing, trust a 5 Axis CNC Machine by 5thCart to do the job accurately and efficiently. It can create complex shapes and high-precision parts that other machines can’t. For example, it can carve a sculpture or mill a complicated engine part with intricate designs all without needing to adjust the material manually.

The Advantages of Using a 5 Axis CNC Machine by 5thAxis

Increased Precision and Detail

The CNC machine can achieve incredibly accurate and detailed results with its advanced movement. This accuracy is very important in aerospace, automotive, and healthcare industries, where even a tiny mistake can cause big problems.

Faster Production Time

Since the machine can complete complex tasks without stopping for adjustments, it speeds up production. This efficiency means companies can make more products in less time, cutting costs and meeting customer needs faster.

Improved Tool Life

The 5 axis CNC machine uses its tools more efficiently. By tilting and rotating the tool the machine makes sure that the cutting implements wear out more evenly which means they last longer.

Significance of 5 Axis CNC Machine in Manufacturing

In the world of manufacturing 5 axis CNC is very important. They allow for the production of parts that are not only complex but also very consistent and uniform. This level of consistency is essential for high-tech industries that need parts to fit perfectly every time. Additionally, educational institutions are recognizing the importance of training students on advanced equipment like CNC machines. Schools and universities are investing in these technologies to prepare students for future careers in manufacturing and engineering. This hands-on experience not only enhances their skills but also their understanding of modern manufacturing processes.

The Advancement and Changes in CNC Machines

The future looks good for 5 axis CNC technology as it continues to get better. With improvements in software and hardware, these machines are becoming more affordable and useful for all types of manufacturing businesses. They are also being used together with other technologies like 3D printing to create even more possibilities. As technology advances, the demand for 5-axis CNC machines in smaller and more creative industries is also growing. Artists, designers, and small workshops are beginning to see how these machines can help them produce unique and intricate products that were once only possible in large factories. The possibilities are expanding rapidly, from custom jewelry pieces to bespoke furniture designs.

Ending Notes

5 axis CNC machines are crucial in today’s manufacturing world. They offer unmatched accuracy, efficiency, and flexibility, making them a key tool in producing complex and precise products. As technology progresses, their role is only expected to increase, pushing the limits of what’s possible in manufacturing. Environmental impact is another area where CNC machines are making a difference. These machines are very efficient with materials and energy, which helps reduce waste and lower the carbon footprint of manufacturing operations. As industries increasingly focus on sustainability the ability to produce more with less is a significant advantage.