Foam Protective Packaging: A Smarter Way to Protect Products

Introduction

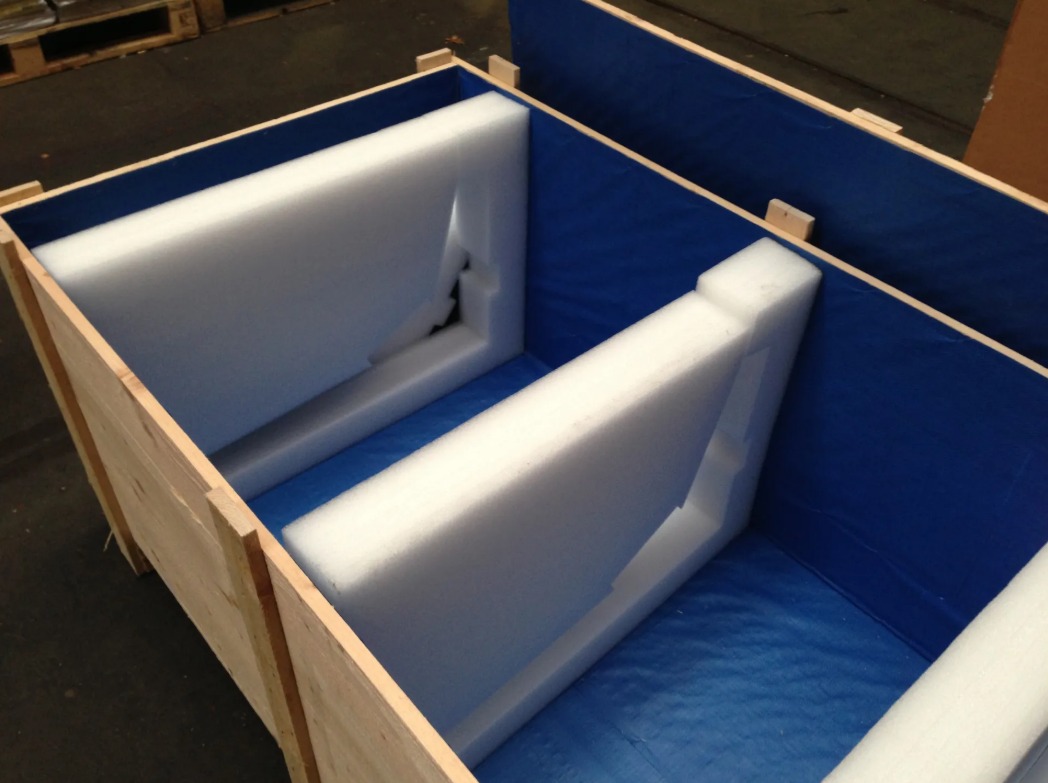

In today’s fast-paced world of e-commerce, logistics, and global supply chains, ensuring the safe transportation of products has never been more important. Businesses cannot afford damaged goods, customer complaints, or costly returns. That’s where foam protective packaging comes in—a versatile and reliable solution designed to keep products safe at every stage of the journey. From delicate electronics to heavy automotive components, protective packaging made from polyethylene foam has proven itself as a leader in durability, performance, and sustainability.

What Is Foam Protective Packaging?

Foam protective packaging is a highly engineered material made from polymers such as polyethylene. Unlike basic cardboard or paper fillers, this foam structure is filled with millions of microscopic cells that act like shock absorbers. This design allows it to:

- Cushion products against vibration and impact

- Prevent scratches and surface damage

- Absorb energy during drops or collisions

- Adapt to a wide range of product sizes and shapes

The result? A protective packaging solution that offers peace of mind for businesses and customers alike.

Polyethylene Foam: The Core of Protection

At the heart of advanced packaging lies polyethylene foam—a cross-linked, closed-cell material engineered for strength and flexibility. Companies across industries prefer this material because it combines lightweight handling with high shock resistance, making it ideal for everything from single-use shipping boxes to reusable multi-trip packaging.

Key Features of Polyethylene Foam:

- Durability: Maintains performance even after multiple impacts

- Moisture Resistance: Prevents damage caused by humidity or condensation

- Chemical Resistance: Suitable for sensitive goods exposed to challenging conditions

- Versatility: Available in colors such as black, white, blue, and anti-static pink to meet industry needs

- Customisation: Can be cut, shaped, or laminated to match unique product requirements

This adaptability ensures that polyethylene foam protective packaging isn’t just generic padding—it’s a tailored solution.

Why Businesses Choose Foam Protective Packaging

When compared to traditional packaging materials such as corrugated cardboard or expanded polystyrene, polyethylene foam stands out for several reasons.

1. Multi-Drop Protection

Unlike materials that break down after repeated shocks, polyethylene foam retains its structure. This is crucial for expensive or fragile products that may encounter multiple handling points during transport.

2. Complete Packaging Service

Manufacturers and suppliers often provide not just the foam inserts but also boxes, cartons, bubble wrap, and tape—creating a one-stop protective packaging solution. This reduces paperwork, simplifies supplier management, and ensures every part of the package is optimized for protection and cost.

3. Sustainability

Modern businesses are under pressure to adopt greener practices. Foam protective packaging is reusable and recyclable, offering a longer lifespan than single-use fillers. This reduces waste and lowers overall packaging costs.

4. Customer Confidence

Safe, damage-free deliveries improve customer satisfaction and reduce return rates. By investing in high-quality protective packaging, businesses strengthen their brand reputation.

Industry Applications of Polyethylene Foam Packaging

📦 Logistics and Distribution

In warehousing and nationwide deliveries, foam inserts and sheets act as shock absorbers, ensuring products arrive in the same condition they were shipped.

🚗 Automotive

Delicate car panels, sensors, and engine components require vibration resistance and careful handling. Polyethylene packaging prevents costly damage during manufacturing and shipping.

💻 Electronics

Circuit boards, laptops, and other electronic devices are vulnerable to static, shocks, and temperature changes. Anti-static polyethylene foam is a trusted protective packaging choice for this sector.

🧪 Healthcare & Pharmaceuticals

Medical instruments, diagnostic devices, and pharmaceutical products demand sterile and secure packaging. Foam protective packaging offers moisture resistance and hygienic storage conditions.

🏭 Manufacturing & Engineering

On assembly lines, foam sheets and inserts prevent scratches, dents, and damage to components while in storage or transit.

Benefits of Foam Protective Packaging

- Cost Efficiency: Reduces product losses, saving businesses money in the long run

- Reusable: Ideal for companies using multi-trip packaging systems

- Lightweight: Minimizes shipping expenses while providing maximum protection

- Custom Fit: Die-cut inserts and bespoke designs ensure every product is securely housed

- Sustainability: Foam is recyclable and supports greener supply chain practices

- Versatility: Suitable for everything from fragile glassware to industrial machinery

Foam Sheets: Stratocell® for Superior Protection

One of the most advanced forms of polyethylene packaging is Stratocell® foam sheets. Known for their high strength-to-weight ratio, these sheets combine outstanding cushioning performance with cost efficiency.

Benefits of Stratocell® Sheets:

- Excellent shock absorption for delicate goods

- Lightweight yet durable for repeated handling

- Non-abrasive surface to prevent scratches

- Moisture-resistant barrier for sensitive products

- Available in various thicknesses, densities, and custom sizes

From electronics manufacturers to automotive suppliers, Stratocell® is trusted for its reliability and consistent performance.

Choosing the Right Supplier Matters

Not all protective packaging is created equal. Businesses benefit from working with experienced suppliers who can provide:

- Customisation to exact dimensions, densities, and shapes

- Complete packaging solutions, including cartons, tapes, and inserts

- Fast turnaround times to meet urgent shipping needs

- Sustainable options that align with corporate responsibility goals

- Expert support to guide product-specific packaging choices

A trusted partner ensures businesses always receive the right balance of cost, performance, and sustainability.

Conclusion

In an era where global shipping is the backbone of business, foam protective packaging has emerged as one of the most reliable, adaptable, and sustainable solutions for safeguarding products. Whether it’s a smartphone, a car part, or sensitive medical equipment, polyethylene foam packaging ensures that goods reach their destination intact—protecting both the product and the brand’s reputation.

By investing in high-quality protective packaging, businesses not only reduce costs associated with damage and returns but also build long-term trust with customers. As industries continue to demand innovative, eco-conscious packaging solutions, foam-based materials such as polyethylene and Stratocell® will remain at the forefront of packaging excellence.